Power Transmission and the Products That Transmit Power to Create Motion

To create motion power transmission products transmit power. Motion is transmitted by the power transmission process from one shaft to another with a connection between them like a belt, chain, or gear. In industrial automation, construction machinery, and material handling system applications PTO shaft products are commonly used.

The transmission method is a method that in terms of energy configuration, movement speed, and motion, form matches the power machine and the working part of the machine. Four power transmission methods are covered with an emphasis on mechanical power transmission.

Mechanical power transmission

Mechanical power transmission is the transfer of energy from its place of generation to a place where it is utilized to perform work using mechanical linkages mechanical power transmission elements and machines.

The advantages that we get are transmitting power efficiently, changing rotational speeds, and converting rotational movement into linear reciprocating motion.

A wide array of things is included in the types of mechanical power transmission elements:

- Power screws – It is used as a power transmission linkage element

- Clutches and Brakes - utilized in the engagement of the transmitted power

- Chains and sprockets - when exact speed ratios are needed it is used to transmit power.

- Belts and pulleys - are utilized when gears cannot be used and between the shafts, the distance is too far apart. In transferring mechanical power, belt pulleys are used. Belts are even considered flexible connectors.

- Shafts - in all types of mechanical equipment design these are used by PTO shaft supplier. To transmit power or rotation components such as couplings, gears, pulleys, and more are mounted onto a shaft.

Electric Drive

In driving types of production machinery, vehicles, and others an electric drive refers to electric motors is used. It converts electric energy into mechanical energy.

Hydraulic transmission

By using the liquid as the working medium Hydraulic transmission is performed by the transmission of energy and control.

Conclusion

For driving the machines and equipment for various applications energy is very much essential. Different power transmission products are used by different industries, PTO shaft manufacturer and sometimes to suit their individual needs a combination of all is used.

Original source: https://gearreducers.wordpress.com/

Know More about Drag Conveyors Right Here

In special transportation of smaller capacities dragging chain conveyors are used. The working of Drag chain conveyors is based on the principle of a chain-and-flight combination pulling a volume of material along. With different flights/paddles, the chain is equipped and points to several discharging points it drags the material from various charging.

Mainly for dusty, abrasive, or hot material, the enclosed conveying device is used and in coal, it has a very limited application. However, specialized conveying systems are needed by the power plant industry and other coal industry players, for which the very flexible drag chain conveyor, might be the only solution. There are many dragging chain supplier who provides good quality products.

To safely move large volumes of product material, handling equipment is used and it performs it with great efficiency. The conveyor is the most common form of this technology that transports material from its inlet to its discharge end via buckets, chains, augers, belts, and more uses mechanized movement. You can understand conveyor systems by visiting different articles as in this article we will learn basics about the drag conveyor. This conveyor class, which is otherwise known as paddle, drag chain, scraper, or en masse conveyors, is a continuous device. It can accelerate bulk products with ease and perform quick aggregates and other materials working. These are quite reliable.

In terms of operation, drag conveyors are not unlike most other conveyors. It is a motor power with an endless single or double-stranded chain of flights which through the bottom of the conveyor pulls or drags material. The chain can be completely enclosed or partially, but in maximum cases, to allow material to be dragged by the flights to the outlet there must be some form of housing.

For dry, free-flowing materials drag conveyors are very well suited and for cement, railway, chemical, agricultural, and other applications these are most useful which need metering and efficient movement of product. They can be horizontal or inclined, but for vertical conveying, their paddles must be designed by a dragging chain manufacturer.

You can find a reliable manufacturing team online that can give you the best deal.

Main source: https://gearreducers.blogspot.com/

Learn the Basics of Jaw Coupling Technology

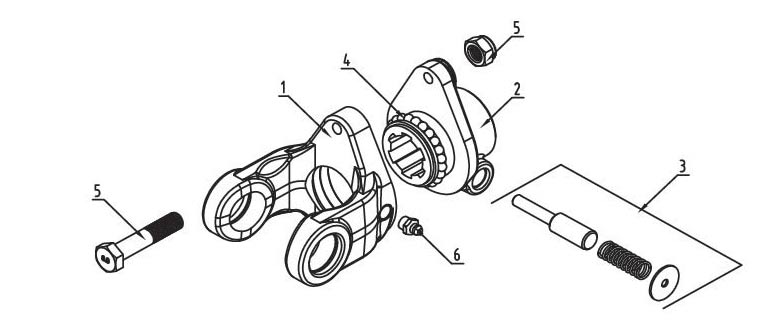

Jaw couplings are made of two jaw coupling hubs that press fit onto a jaw coupling spider and are a three-piece assembly. On the center of the spider's limbs, the press-fit concentrates its force and it allows the coupling to operate with zero backlashes In servo-driven systems, jaw couplings are commonly used that too with high acceleration and deceleration curves where there is a requirement of precise motion control and a low inertia balanced design is required.

According to elastomeric elements transmit torque between driving and a driven hub the classification of all elastomeric couplings is done but the elements are either in compression or shear.

In jaw couplings, in compression between the jaws of mating hubs, the element is loaded. The operation of jaws is done in the same plane, with the driving hub jaws pushing toward the driven hub jaws. Jaw couplings are widely used.

But in shear-type couplings, the operation of driving and driven hubs is done in separate planes, in which the driving hub pulls the driven hub with the help of an elastomeric element suspended between them. You will find different jaw coupling wholesale around you.

Capabilities

In four areas compression type couplings offer you benefits: torsional stiffness, safety, load capacity, and easy installation. At first, all elastomers especially synthetic rubber has higher load capacity in compression when compared to shear.

Second, compared to shear types, compression types offer more torsional stiffness (less twist between hubs) with few versions closely approaching the very stiff characteristic of metallic couplings. Between the motor and driven machines, the backlash is minimized by this high torsional stiffness. For each incremental movement of the driving shaft, it offers the near-equal movement of the driven shaft which is among the important factors in certain conveyor and pump applications.

Third, jaw couplings are fail-safe: even if the spider breaks the coupling can still operate. At a convenient time, the jaw coupling supplier can thus replace the spider, which in downtime can prevent critical systems. Only for this reason, in a well-designed and manufactured coupling, the jaws withstand several times the coupling's torque rating.

Flow-Through the Details of a Conveyor System

Transporting material with minimal effort, conveyor chain is assemblies or mechanical devices. They usually consist of a frame supporting a belt, wheels, or rollers, upon which materials move from one place to another while there are various types of conveyor systems. By manually, by gravity, or motor, they may be powered. To suit the different materials or products that need to be transported, these material handling systems come in many varieties.

Important Conveyor Systems Specifications

Maximum Capacity of Load

This value can be stated for purpose-built or fixed-length conveyors, associated with Load Capacity per Unit Length. This is also denoted as flow rate.

Frame Configuration

The shape of the conveyor frame from the conveyor chain supplier is frame configuration. Frames can be z-frames, curved, straight, or other shapes.

Rated Speed / Conveyor Belt System Speed

In terms of belt speed in ft/min, Belt conveyors are typically rated while in similar units, powered roller conveyors described the linear velocity to a carton, package, etc. moving over the powered rollers. Rated speed applies to two conveyors, drag/chain, slat conveyors, and apron as well.

Belt

Using continuous belts to convey material or products, Belt Conveyors are material handling systems. In an endless loop, the belt is extended between two end pulleys.

Usually, a roll is present on one or both ends underneath. By either a metal slider pan for light loads, the conveyor belting is supported were to cause drag or on rollers, no friction would be applied to the belt. Motors using either constant or variable speed reduction gears offer power.

Numerous materials can be used to make up the belts themselves, which under which the belt will be operating should correspond to the conditions. Metal, plastic, rubber, fabric, and leather are common conveyor belting materials. A thicker and stronger construction of conveyor belting material is required, which is indicated by transporting a heavier load. Depending on the throughput required, Belt conveyors can be operated at various speeds and are typically powered. The conveyors from the conveyor chain manufacturer can be made inclined or can also be horizontally operated. For large or bulk materials, Belt conveyors can be troughed.

Get Acquainted with the Sprockets Chains in Details

Used to convey materials or transmit power by engaging with conveyor or roller chains, chain sprocket is rotating toothed wheels. Key specifications are the pitch, material, intended application, and physical dimensions as well as several teeth as required.

In chain-driven systems, Sprockets are used primarily to transmit rotation or power to other shafts. An example is transmitting rotation from the pedals to the wheel, a bicycle sprocket. To convey material from place to place, Sprockets may also be used as in the case of overhead conveyors. Based on the intended application and chain type, Sprockets come in a variety of tooth configurations.

Applications and Industries

Anywhere gears might be required but where the distance between shafts centers makes them impractical, Power transmission sprockets are used. To synchronize and drive camshafts with crankshafts, automotive engines use sprockets and chains. Often, these are multiple sprockets driving triple or double-wide roller chainsets. In housed environments, Gears function better with lubricant sumps, etc. On proper tension and alignment, Chains are also dependent during their initial installations and regarding these parameters, most chain manufacturers give detailed advice. As compared to gears, Chains from chain sprocket supplier tend to be noisier although inverted-tooth. Hence, they are known as silent chains. As compared to what gears exhibit, they also have lower speed capabilities.

As compared to their power transmission counterparts, engineered chain sprockets tend to be beefier than owing to the extra loads put on the chains as conveyors, etc. Sometimes these chains are called mining chains, lumber chains, agricultural chains, etc. and at the links which the sprockets sometimes must accommodate, they are often fitted with attachments.

Making it possible to replace worn teeth, some engineered chain sprockets are fitted with bolt-on tooth sectors. This replacement can be done without eliminating the sprockets and undoing the conveyor chains from their drive shafts.

By pitch and number of teeth, engineered chain sprockets and Conveyor chain sprockets are also commonly designated but owing to the larger pitches common with these elements, the pitch is a direct numerical measure often.

Wherein the sprocket from chain sprocket manufacturer contains an odd number of total teeth distributing the wear among two sets of teeth for increased longevity and extra half-pitch teeth, some conveyor chain sprockets employ a hunting tooth arrangement.

The Benefits of the Various Systems with Tractor Transmissions

For many greenkeepers and groundsmen, Tractors are a part of daily life. They are the beasts of burden: powering attachments, towing trailers, loading trailers, towing mowers, and tipping loads like sprayers and aerators.

Available on agricultural gearbox of a modern tractor, one of the major changes has been to the transmission systems and when purchasing a new machine, the choice that the potential buyer faces. In this article, we try to establish the benefits of each transmission type and look at the current offerings.

Manual Transmissions

On operating a clutch to change range, gears, and to disengage or engage, the PTO drive by use of a 2 stage clutch, the original drive system relied where partial depression disengaged only the gearbox and full depression stopped all drives.

Removing the need for a two-stage clutch, Today's PTO drives are all independent.

Originally, between the driver's legs, the gear levers were situated on top of the gearbox. Allowing a wide spread of forwarding speeds and full engine power, one for the gears and a second lever which changed the ranges, There were two levers.

Shuttle shift: Today, there isn't a reverse gear separately. Instead of allowing a change of direction, we have a reverse and forward lever, without having to change the gear of the tractor. So, we have twelve reverse gears and twelve forward, if we have twelve gears from an agricultural gearbox supplier!

Intelligent Transmissions: to change gears, the latest manual transmissions now allow the driver and without using the clutch, to change direction. By pressing a down or up button on the gear stick, an electronic gear change is achieved, and by using a shuttle lever, a forward-reverse is selected. Making it easier for the driver to operate safely, the shuttle gives an additional neutral. Selecting the speed range the tractor is going to be working in the only time the clutch has to be used from an agricultural gearbox manufacturer.

So, the modern manual transmission has come a long way from an operational point of view. This is critical for accurate fertilizer and spraying, applications, the benefits of positive gears are a fixed forward speed, the essential turf maintenance task of aerating.

The Function and Usage of Gearboxes

From a rotating power source to another device using gear ratios, a gearbox provides torque and speed conversions. It can be used in various situations such as pedal bicycles, fixed machines, and anywhere else rotational torque and speed need to be adapted. But, in motor vehicles, the most commonplace is where the drive wheels, the gearbox with taper bush adapts the output of the internal combustion engine. They cannot be used in many operations such as stopping or starting as these engines need to be operated at a relatively high rotational speed.

They must be largely used in cars as gearboxes are so widely used in motor vehicles. More and more cars are consumed with the development of our economy as a result, gearboxes are playing a more crucial role in our daily life. Few of them have the knowledge of how a car works although many people have cars, let alone the relationship between various mechanical components. For car owners, It is a wise decision to learn something about gearboxes from a taper bush supplier as car gearboxes are the basic parts for its working process.

To the crankshaft of the engine, the gearbox will generally be connected in cars. And driving the wheels, the output of the transmission via the drive shaft is transmitted to various differentials. Pushing the car forward, the gearbox converts engine speed into torque. It is the major job of the gearbox. Between automatic cars and manual cars, there is some difference.

Used in many other places except in cars, there is no doubt that gearboxes from taper bush manufacturer. But no matter where they are used i.e. the gear ratio cannot be changed during the usage, these transmissions share an important feature. It is because at the time the transmission is set, the gear ratio is fixed.

All in all, there is more knowledge about their functions and gearboxes. Of gearboxes, you should have some basic knowledge. In your future life, maybe it will be helpful.

Follow our Facebook and Twitter for more information about our product.